Cartridge heaters are versatile, compact heating elements widely used in industrial applications, from injection molding and packaging machinery to medical devices and food processing equipment. Proper installation and regular maintenance are essential to ensure these heaters operate efficiently and reliably over their intended lifespan. Below are some valuable tips to optimize your cartridge heater performance.

Installation Tips

- Correct Hole Sizing

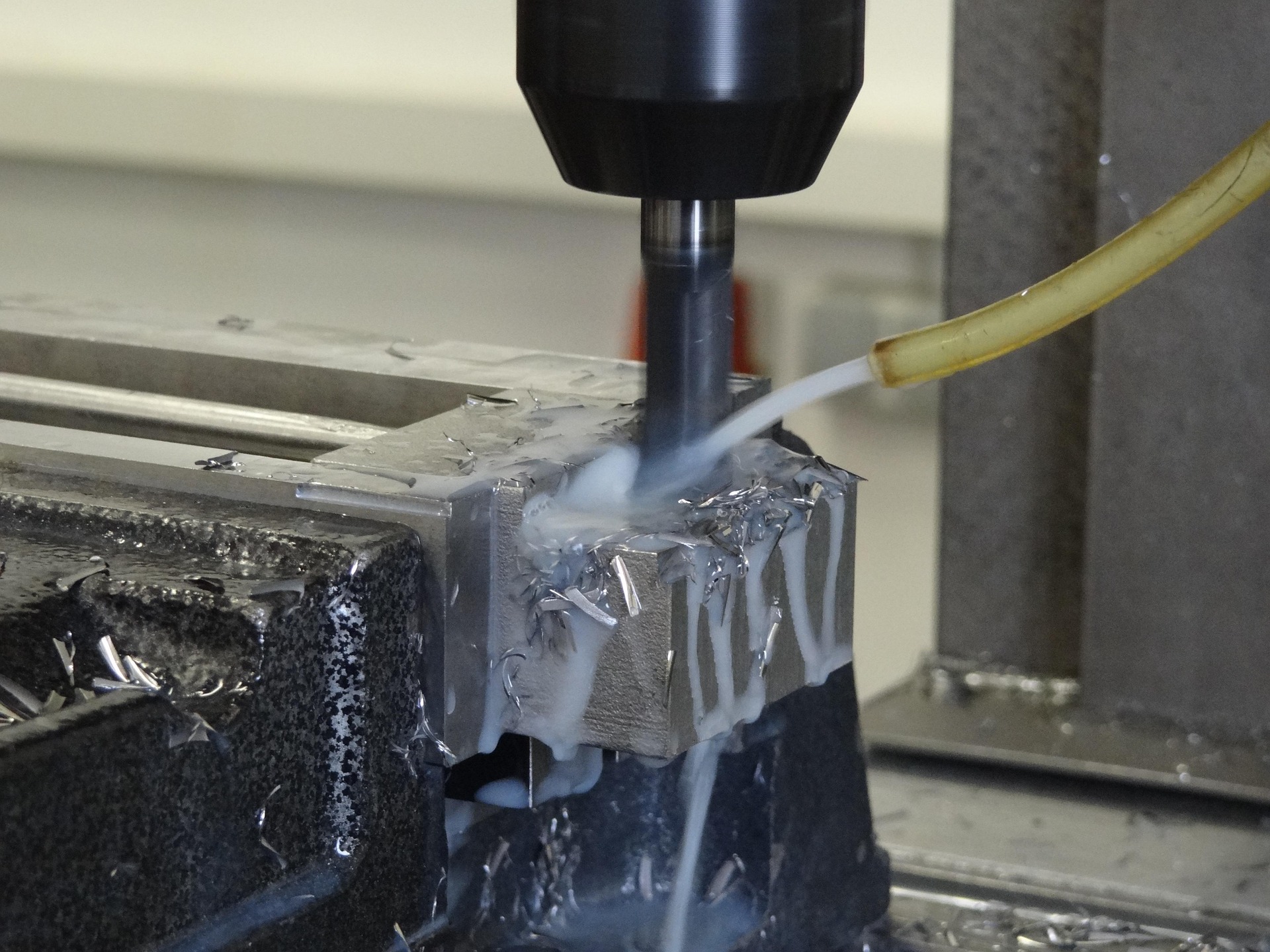

Always drill a properly sized hole for your cartridge heater. An undersized hole can prevent installation or damage the heater, while an oversized hole reduces heat transfer efficiency and shortens heater life. Typically, holes should be no more than 0.005 inches larger than the heater diameter. - Heater Insertion and Removal

Insert cartridge heaters carefully and avoid forcing them. Using thermal grease can improve heat transfer, simplify insertion, and ease future removal. - Protect Leads and Connections

Ensure that heater leads are not subjected to tension or excessive movement, as this can lead to early failure. Utilize appropriate strain relief fittings and avoid sharp bends or twists. - Temperature Control

Pair cartridge heaters with suitable temperature sensors and controllers. Overheating can dramatically shorten heater life, so always ensure appropriate temperature monitoring and control.

Maintenance Tips

- Regular Inspection

Routinely inspect cartridge heaters for signs of wear, corrosion, or damage. Replace damaged heaters promptly to avoid disruptions in production. - Cleanliness

Keep cartridge heaters and their installation areas clean and free of contaminants such as dirt, oil, or debris. Contaminants can cause hot spots or uneven heating, leading to premature failure. - Monitor Heater Performance

Regularly measure heater resistance and compare it against manufacturer specifications. Deviations can indicate internal damage or impending failure. - Scheduled Replacement

Replace cartridge heaters proactively based on operating hours or cycles rather than waiting for a failure. This practice minimizes unexpected downtime and maintains optimal efficiency.

Troubleshooting Common Issues

- Uneven Heating or Hot Spots: Check for an improper fit or contamination in the heater bore. Cleaning and proper sizing can correct these issues.

- Frequent Heater Failures: Inspect lead wires and connections for stress, overheating, or corrosion. Ensure appropriate watt density and temperature control settings.

- Slow Heating or Inefficient Performance: Verify heater-to-hole fit and confirm the heater is operating within its rated wattage and voltage.

By following these installation and maintenance tips, you’ll maximize your cartridge heater performance, reduce downtime, and extend the life of your heaters. Regular attention and proper care ensure your processes remain consistent, efficient, and reliable.

Contact us to speak to one of our engineers about any questions with installation or maintenance of your cartridge heaters.