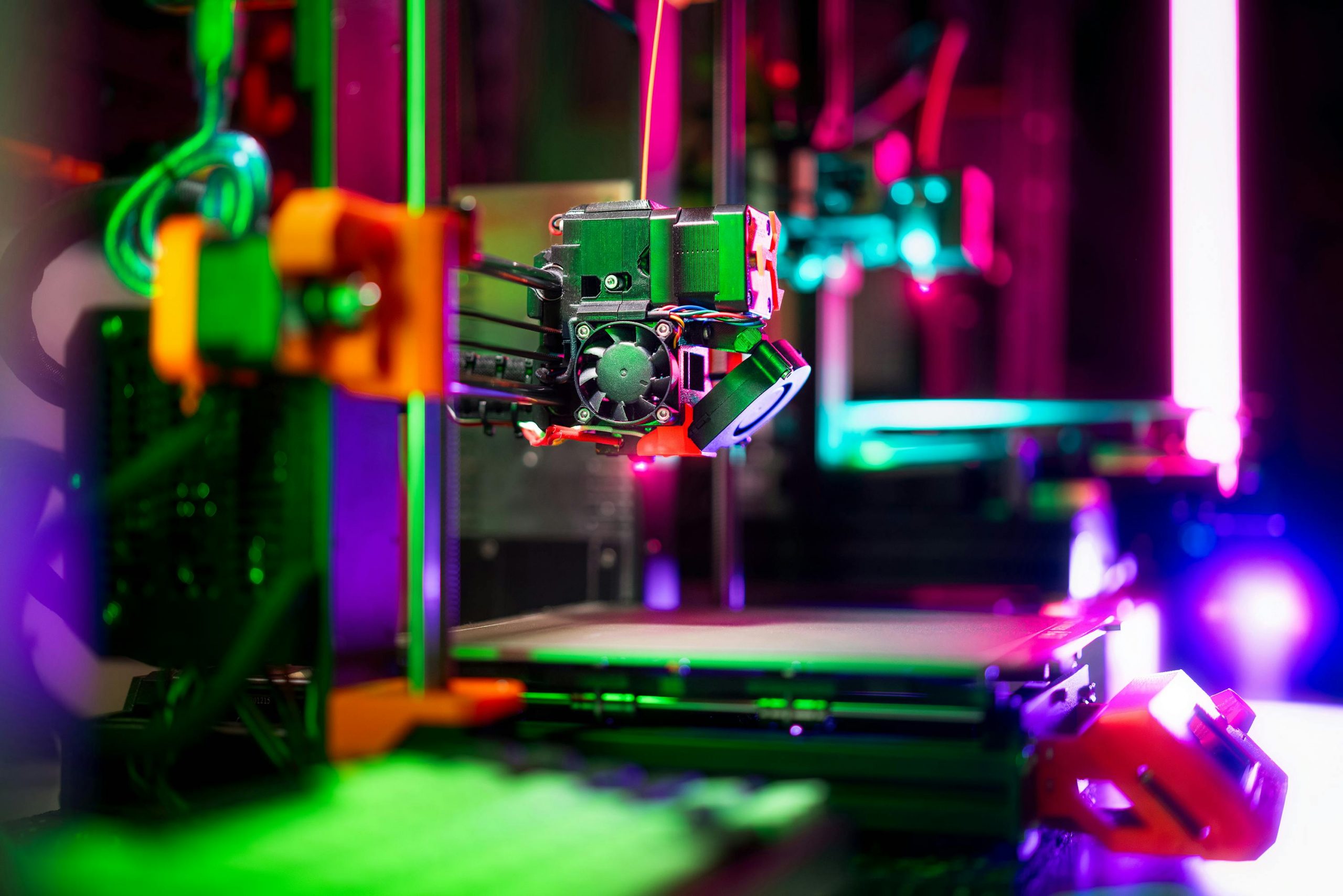

3D printing has revolutionized manufacturing by enabling rapid prototyping and on-demand production of complex designs. One of the key components behind the scenes ensuring precise and reliable operation is the cartridge heater. These compact and efficient heating elements play a critical role in maintaining the optimal temperatures required for 3D printing processes.

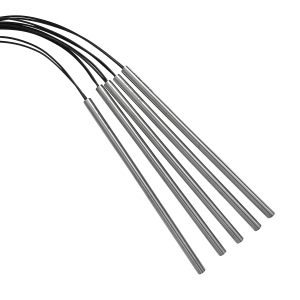

What Are Cartridge Heaters?

Cartridge heaters are cylindrical heating elements typically made from stainless steel or Incoloy—materials chosen for their high-temperature resistance and durability. Inside the heater, a coiled resistance wire is surrounded by magnesium oxide, which acts as an electrical insulator and an efficient thermal conductor. This structure ensures uniform heat distribution and quick response times.

Key Applications in 3D Printing

In the realm of 3D printing, cartridge heaters are primarily used for:

- Extruder Nozzles

- The extruder nozzle is where the 3D printer’s filament melts and is deposited layer by layer. Cartridge heaters maintain precise temperatures in the nozzle, ensuring consistent melting and extrusion of materials like PLA, ABS, PETG, and nylon. Temperature control is essential for avoiding clogs, ensuring strong layer adhesion, and achieving high-quality prints.

- Heated Beds

- Some 3D printers use cartridge heaters to warm the print bed. A heated bed minimizes warping and ensures that the first layer of the print adheres properly. This is especially important when working with high-temperature filaments or large prints.

- Chamber Heating

- For industrial 3D printers, especially those working with advanced materials like PEEK or ULTEM, maintaining a heated build chamber is crucial. Cartridge heaters provide the necessary heat to keep the chamber at consistent temperatures, reducing stress in the printed parts and improving overall mechanical properties.

Why Cartridge Heaters Are Ideal for 3D Printing

- Precision

- Cartridge heaters can be equipped with built-in thermocouples, allowing for precise temperature control. This is vital in 3D printing, where even small temperature fluctuations can affect print quality.

- Compact Design

- Their small size makes cartridge heaters easy to integrate into tight spaces such as nozzles and print heads, without compromising efficiency.

- Durability

- 3D printing environments can be demanding, with constant heating and cooling cycles. Cartridge heaters are designed to withstand these conditions, providing long-lasting performance.

- Rapid Heating

- The efficient thermal transfer properties of cartridge heaters allow for rapid heating, which minimizes downtime and improves printer responsiveness.

Selecting the Right Cartridge Heater

When choosing a cartridge heater for a 3D printer, consider the following factors:

- Wattage and Voltage: Ensure the heater matches the power requirements of your printer.

- Size: The diameter and length of the heater should fit snugly into the intended component.

- Temperature Range: Choose a heater that can achieve the required temperatures for your printing materials.

- Material Compatibility: Ensure the heater’s sheath material is compatible with your operating environment.

Cartridge heaters are indispensable in 3D printing, providing the precise and reliable heating needed for consistent, high-quality results. Whether it’s melting filament, stabilizing a heated bed, or maintaining chamber temperatures, these versatile devices contribute significantly to the success of 3D printing projects. By understanding their role and selecting the right specifications, manufacturers and hobbyists alike can enhance their 3D printing performance and achieve outstanding results.

Interested in learning more about cartridge heaters for 3D printing? Check out our catalog of high-performance cartridge heaters, or request a quote for a custom solution!