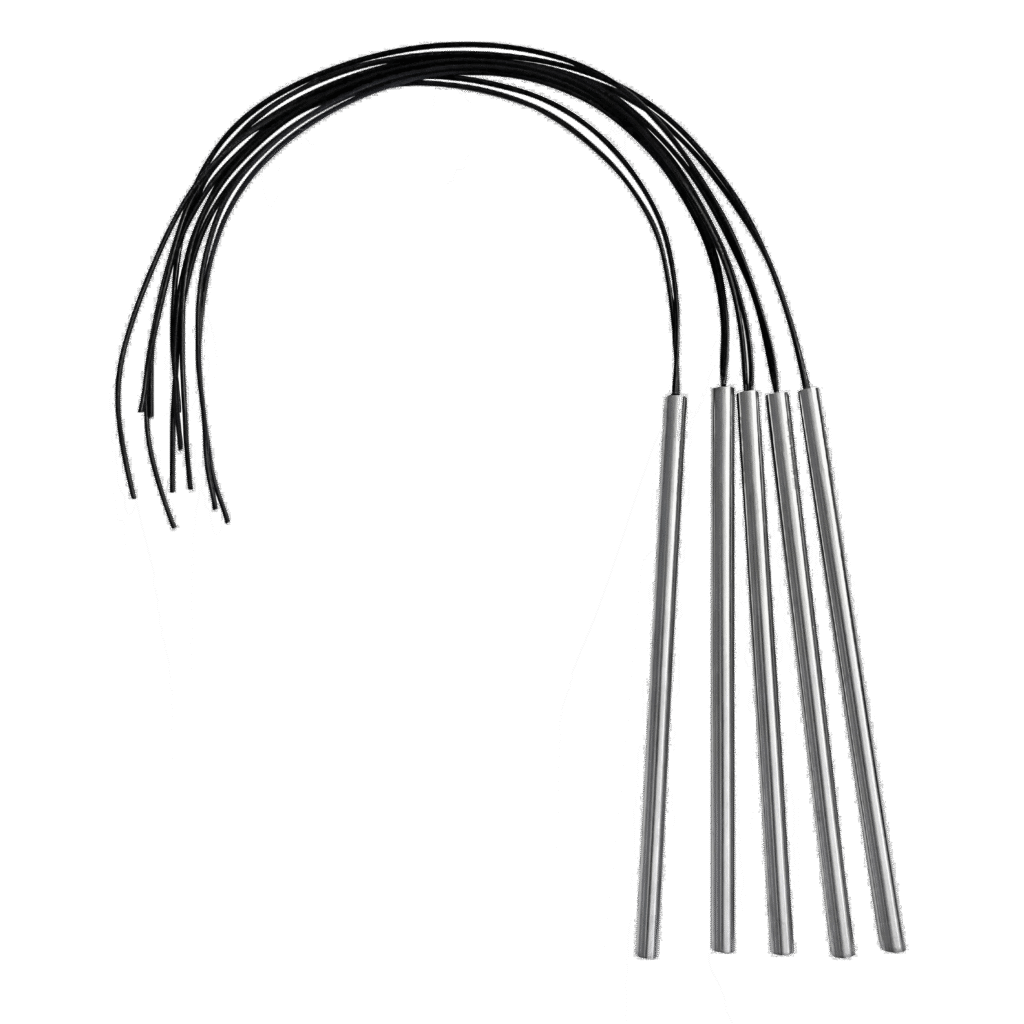

Cartridge heaters are cylindrical shaped, rugged heating elements which operate on the principle of Joule heating. Cartridge heaters provide high-precision, uniform heat for demanding industrial and laboratory processes. We wind a resistance-wire element around a magnesium-oxide (MgO) core, then seal it inside a stainless-steel or Incoloy sheath. Simply insert the heater into a matching bore to achieve faster, more consistent heating than alternative methods.

Why Choose Cartridge Heaters?

- High Watt Densities

Reach surface temperatures up to 1400°F (760°C) without degrading performance—ideal for extreme environments. - Rugged Durability

Stainless-steel or Incoloy sheaths withstand mechanical stresses, vibration, and corrosion. - Customizable Designs

Pick your diameter, length, voltage, and wattage to match every application.

Key Features

- Lead-Wire Options

- PTFE, silicone, or fiberglass insulation

- Reinforced strain-relief to prevent bending fatigue

- Built-In Temperature Sensing

- Integrate a thermocouple inside the sheath

- Enable real-time feedback to your PID controller

- Flexible Mounting

- Threaded fittings, flanges, or compression seals

- Secure your heater precisely where you need it

Common Applications

- Process Heating: Extrusion, sealing, laminating, 3D printer hot end control

- Water & Fluid Heating: Injection molds, hot-runner systems

- Platen & Press Heating: Thermoforming, die cutting

- Laboratory Equipment: Drying ovens, analytical instruments

- Mold & Die Heating: Injection molding, blow molding

Installation & Maintenance Tips

- Optimize Fit: Pair with a drilled bore ~0.005″ larger than your heater diameter.

- Inspect Seals: Check lead-wire seals and connections every 3–6 months to prevent moisture ingress.

- Maintain Control: Pair your cartridge heater with a PID controller to avoid temperature spikes and extend heater life.